The rapid introduction of new technology, new regulations and the overall cost of safely operating a diving or submarine capability present new challenges to designers and operators alike. QinetiQ is at the forefront of Maritime Life Support services to maximise operational effectiveness, efficiency and safety for submarine escape and rescue systems, atmosphere control systems and diving kit.

Harnessing over £100million of specialist test facilities and equipment, we deliver bespoke solutions for an international client base - both defence and commercial – to meet the specific challenges of diving in all environments, escaping from disabled submarines and controlling the air people breathe on-board submarines. Our highly qualified and respected experts provide significant technical and operational advantage for customers by delivering unique and exceptional outcomes.

QinetiQ’s reputation and heritage in diving has evolved from the deep diving research programmes of the 1960s and 70s, including a world record 660 m dive in the High Pressure Chamber Unit (HPCU) in 1984. Continual investment in new capabilities helps us to build on this legacy and enable our Maritime clients to capitalise on advances in technology and to operate to the highest standards safely and efficiently at all times.

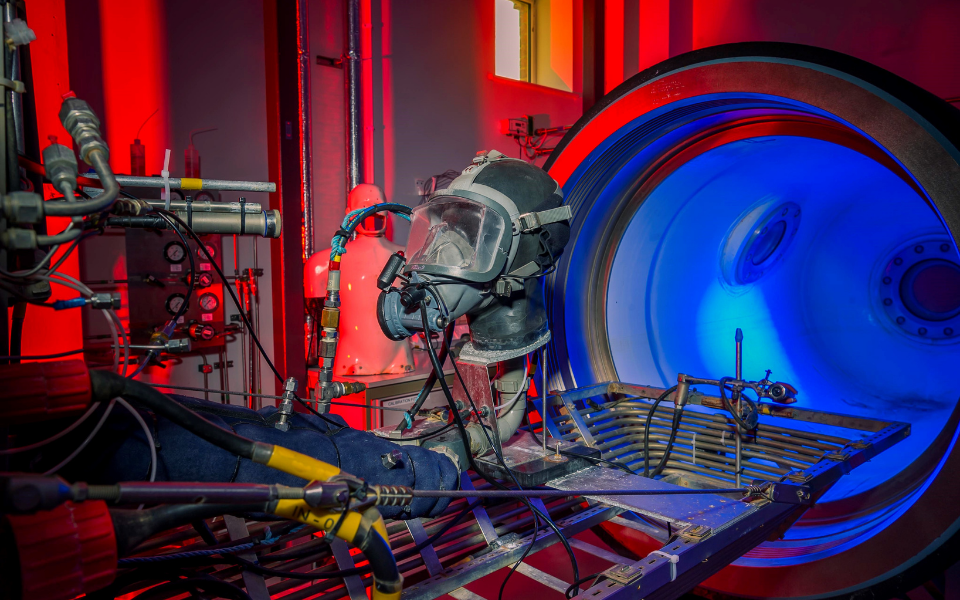

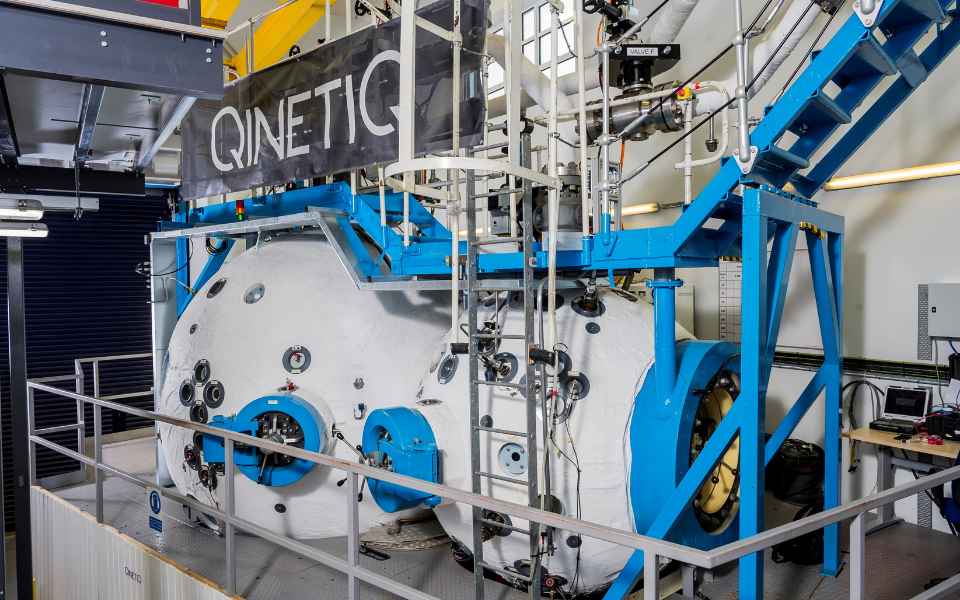

Hyperbaric Trials Unit (HTU)

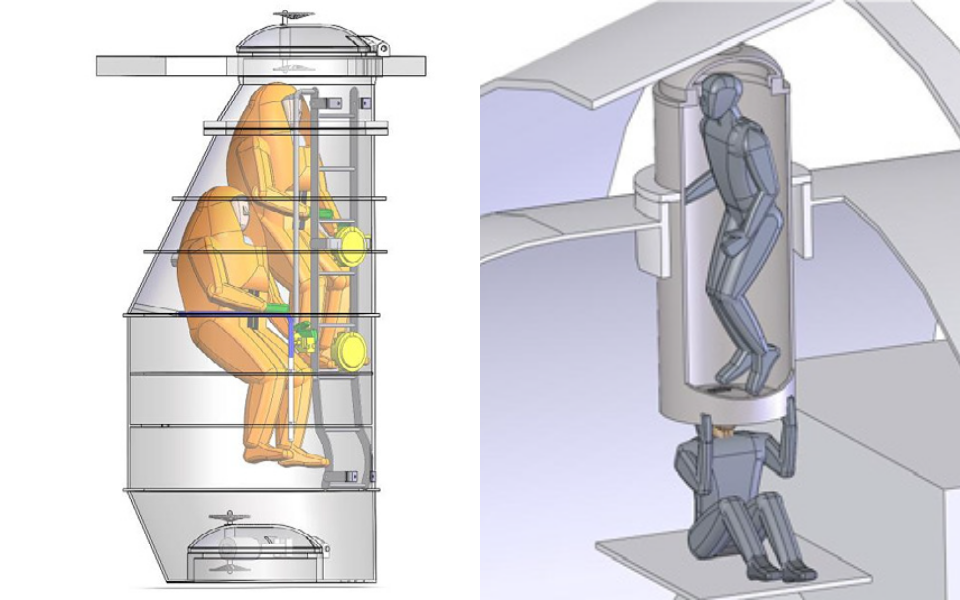

Our hyperbaric trials unit (HTU) is used to test and evaluate escape systems and components to 150 bar. Significantly, the unit enables us to recreate the actual pressure conditions of escape from a submerged submarine independent of the performance of the components under test.

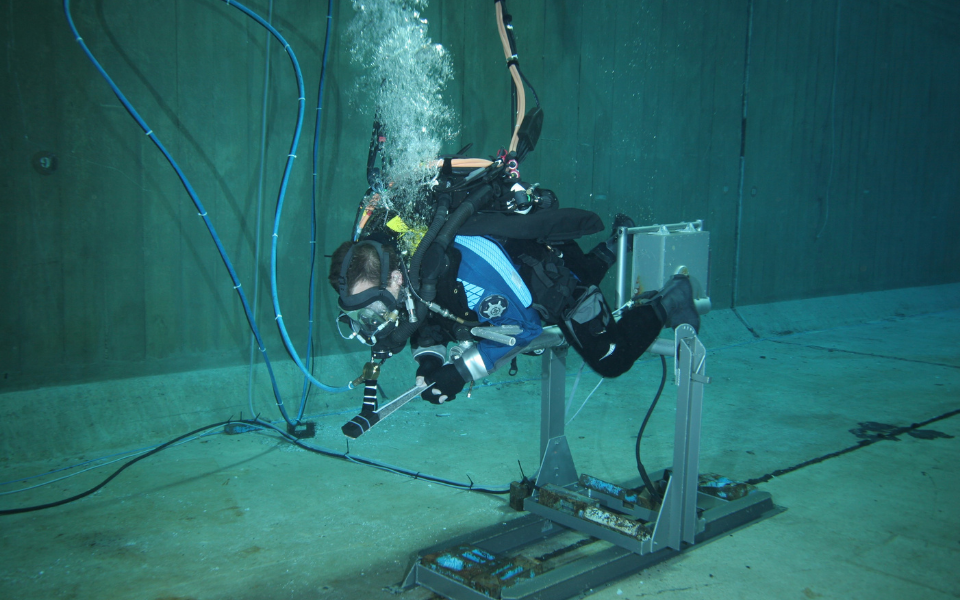

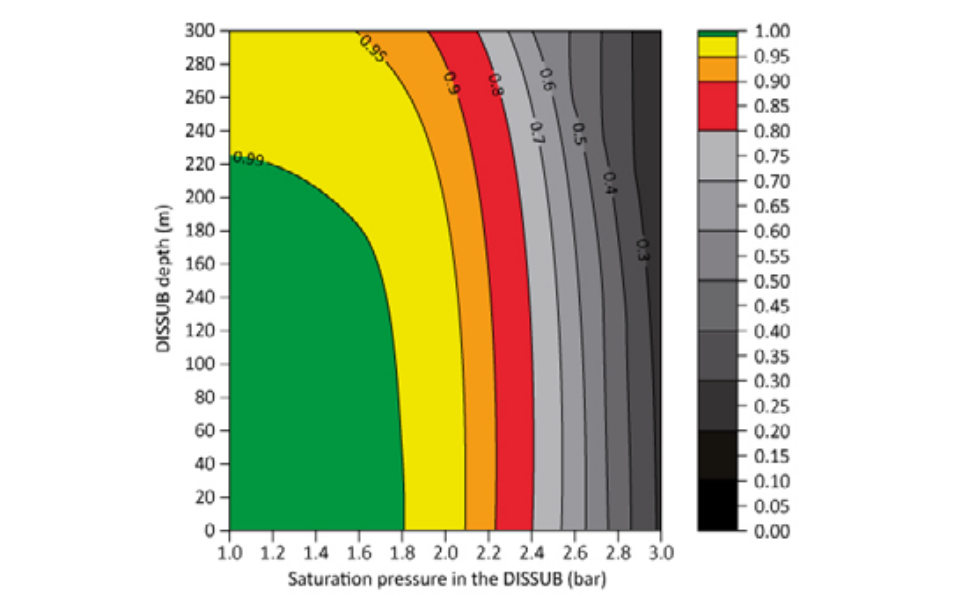

Diving Performance & Optimisation

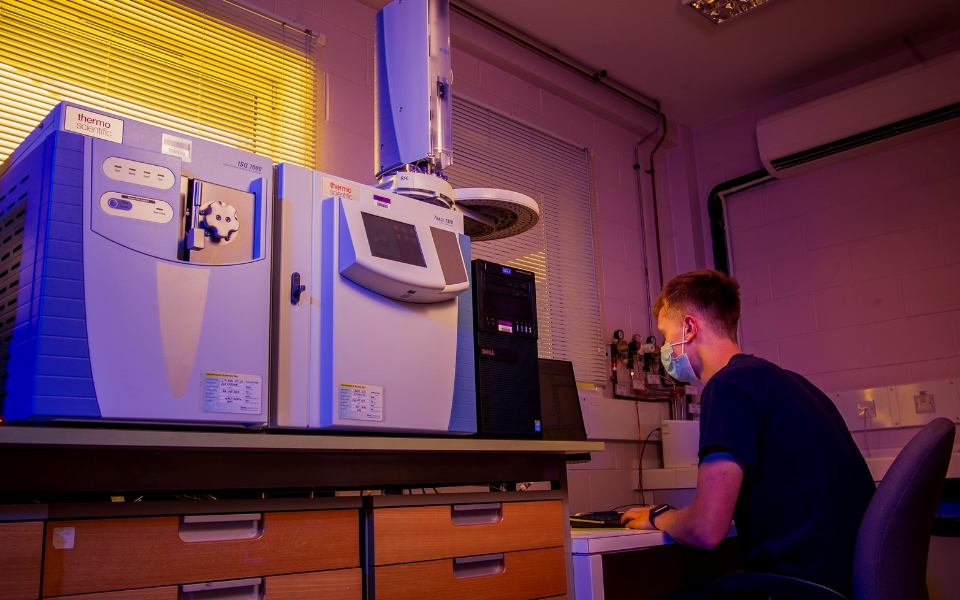

Our diver performance optimisation, testing and advice services include acoustic protection, breathing gas optimisation, decompression and ergonomic evaluation, together with UKAS accreditation for our breathing gas and carbon dioxide absorbent analysis.

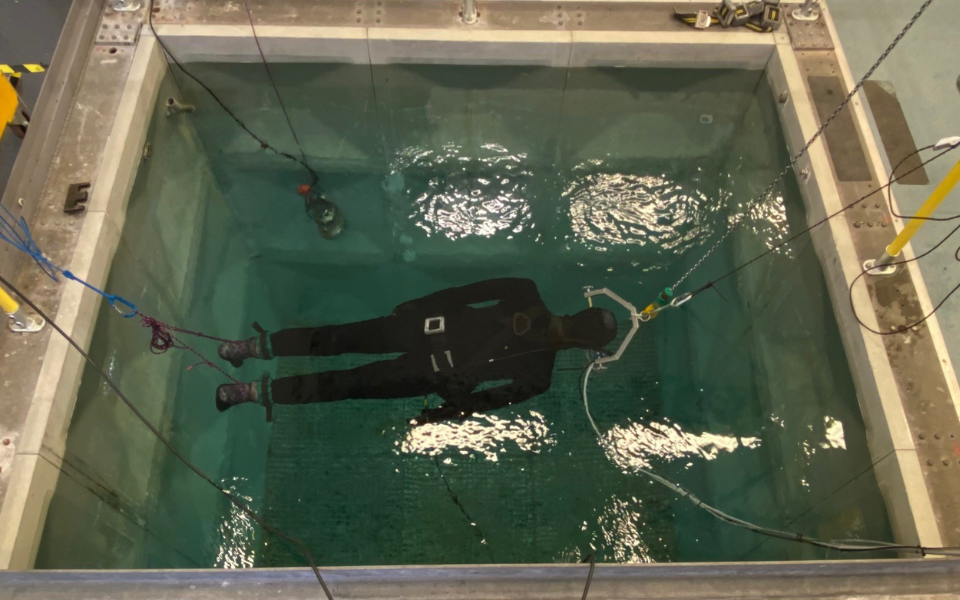

Submarine Escape, Rescue, Abandonment Services (SMERAS)

We provide a full range of tried and tested SMERAS Support Services that have been delivered to many of the world’s submarine fleets - including Fully Instrumented Tower Trials (FITT) and Guardbook advice.

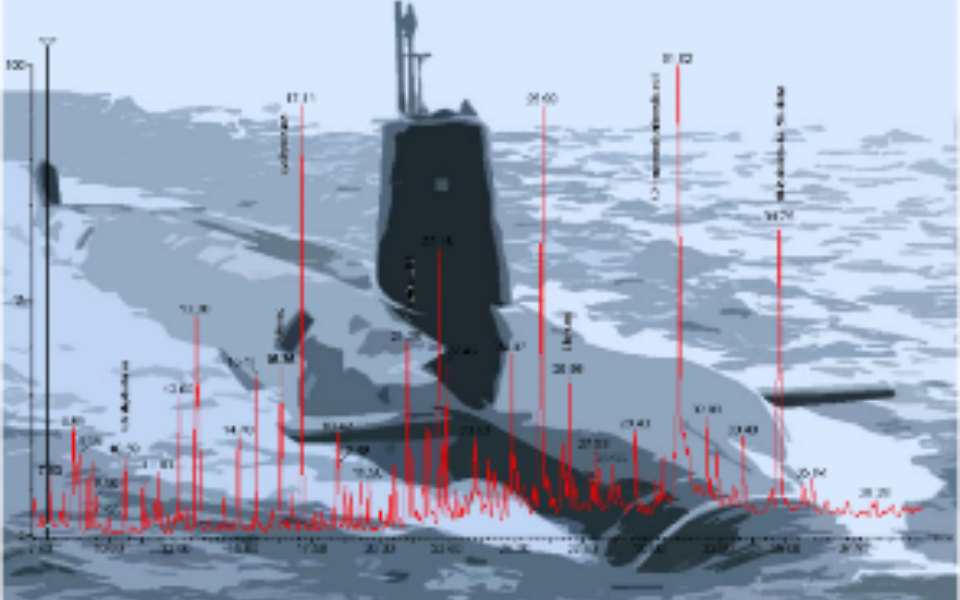

Atmospheres

With over 30 years of experience, we are established leaders in the modelling and assessment of enclosed atmospheres as well as assessment of monitoring equipment in complex enclosed atmospheres.